3D Printing Phoenix allows designers to easily turn their CAD models into physical entities. It also enables manufacturers to produce products on demand, reducing inventory and warehouse space.

The most important element to understand is the printing process itself. The slicing software turns your design into a file that the printer can understand.

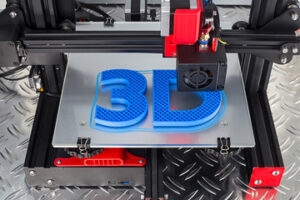

3D printing is an additive manufacturing process that builds items layer by layer until the final object is complete. It is the opposite of traditional subtractive manufacturing methods that create items by cutting or hollowing out material blocks such as milling machines. 3D printing is used for producing lightweight geometric parts with geometries that would be difficult or impossible to produce using traditional manufacturing methods.

Its use is expanding beyond prototyping to creating a wide variety of finished products including shoes, furniture, wax castings for jewelry and tools, art sculptures and toys, medical devices and prosthetics. Engineers are using it for rapid product development and testing, as well as for creating specialized jigs and fixtures that can streamline machinery assembly or maintenance. Consumers are purchasing it to make a wide range of items, from toys and household gadgets to food.

There are a number of different types of 3D printers and technologies that each offer unique capabilities. However, they all share the same fundamental operation style of adding layer after layer of material until the final printed item is complete. They can be categorized by the type of material they work with, the method they employ to fuse or melt materials together, and the method they use to create layers of the final printed item.

One of the earliest technologies, stereolithography, was patented in 1984. It uses UV light to cure photopolymer materials, which are then cured layer by layer until the object is complete.

Other 3D printer technologies include fused deposition modeling, which involves extruding thermoplastic materials such as ABS (Acrylonitrile Butadiene Styrene) or PLA (Polylactic Acid) through a heated nozzle. The molten plastic solidifies into thin layers and hardens into the final printed product. Another popular technology, selective laser sintering, works by heating materials to a temperature that causes them to bind together without melting them.

In addition to these consumer-grade printing technologies, there are many industrial 3D printers that are designed to be used to produce parts for industries such as aerospace and automotive engineering. They also have a role in healthcare where doctors can print models of tumors or organs to help plan surgeries and replicate the interior structure of bodies that would be difficult or impossible to replicate with other techniques.

3D Printing Materials

The materials that 3D printers use to create objects vary, though plastic remains the most popular. However, other options are beginning to take hold in the industry.

For example, wood filaments offer the same benefits as polymer materials but look and feel like the real thing. They are also environmentally friendly and cost-effective. Then there’s carbon fiber, which is the manna of aftermarket automakers and race teams, enabling them to quickly produce parts that are lighter than injection-molded parts and with the same strength, while still meeting design requirements for stiffness and impact resistance.

Metal is a growing option as well, with the popularity of Direct Metal Laser Sintering (DMLS). During DMLS printing, metal powder is distributed layer by layer and then heated to form the desired shape of the finished part. The process eliminates the need for casting and enables manufacturing to occur faster than with traditional processes. It’s also ideal for making components that might come into contact with water or other liquids.

In fact, this type of printing is already transforming several industries. It’s helping engineers and designers develop designs much more quickly than before, and it’s allowing companies to bring their products to market more rapidly. In one case, a company used 3D printing to turn a CAD design into a set of 500 high-precision drilling caps for Airbus. This cut production time from weeks to just three days, enabling the company to begin testing them.

While many types of metal can be printed using DMLS, stainless steel is a particularly desirable material. It offers exceptional mechanical properties, including excellent tensile strength and good flexibility. It’s also resistant to corrosion, rust and fatigue. In addition, it can be electro-polished to improve surface finish.

Other options include abrasion-resistant titanium, which is used for medical devices and aerospace components, as well as alumina, a common ingredient in dental implants. Bronze is another popular choice for aesthetically pleasing fixtures and decor. And for a more luxurious touch, gold can be printed to make jewelry.

In addition to these popular choices, there are a number of specialty materials. Technical ceramics are a group of hard, inorganic materials that are known for their high strength-to-weight ratio, good thermal properties and good chemical resistance. Examples of these include aluminum nitride, zirconia and silicon carbide.

3D Printing Software

When you use a 3D printer, the software you choose can make the difference between digital designs and tangible creations. Top-tier software solutions can interpret intricate geometries accurately and provide users with a seamless workflow, transforming their ideas into tangible reality.

CAD software is an integral component of 3D printing, serving as the backbone for designing a 3D model and creating a bill-of-materials. Suitable for both professional and casual users, it can create accurate representations of geometric shapes, making it ideal for engineering and industrial design projects. It can also serve as a powerful tool for prototyping, enabling engineers to test and modify parts without the need for expensive injection molding.

There are many different types of CAD software available, from free and open-source options like Blender and Meshmixer to paid programs such as Autodesk Fusion 360 and Alias Inventor. Each of these programs is designed to address the needs of a specific audience, with some software best suited for beginners and others more advanced users.

STL editors and mesh repair tools are specialized programs that can be used to prepare digital models for 3D printing. They can help users reduce file size, repair mesh errors, and change the shape of a model. They can also be used to add supports for overhangs and make other modifications to a model. Most of these programs are based on the RepRap open-source movement and can be found in both hobbyist and commercial settings.

Slicing software is another critical piece of the 3D printing puzzle, converting digital models into instructions that can be read by a 3D printer. It can be used to specify slicing parameters, adjust print settings, and visualize the 3D printing process in real time. Among the most popular 3D printing slicing software is Cura, developed by Ultimaker.

Other important tools for preparing digital models for 3D printing are support generation, which helps to minimize warping and warping of the part, and slicing optimization, which reduces a model’s infill density while still maintaining a high level of strength. Support generation software can be found in programs such as Simplify3D and Autodesk Inventor, while slicing optimization is available in programs like Simplify3D and PrintRun.

3D Printing Process

Unlike conventional manufacturing methods, 3D printing creates parts by slicing and melting layers of material to form the desired object. It uses a variety of materials, is typically fast and has lower fixed setup costs than injection molding and machining. It also enables manufacturers to produce bespoke parts in small, customised batches, improving inventory management and shortening design and production cycles.

The process is based on computer-aided design (CAD) or 3D scanning software that produces a digital model of the part to be printed. This is then exported as a file, typically in the STL or OBJ format, which is read by 3D printer preparation software that specifies print settings, including orientation, support structures (if required) and layer height. It may also include adjustment instructions for the type of 3D printing technology.

Different 3D printing technologies have different advantages and limitations. Sintering processes like powder bed sintering, direct metal laser sintering and selective laser sintering use heat to melt and fuse the material together into the finished product. Melting techniques such as direct energy deposition and electron beam melting use a laser, electric arc or electron beam to melt and fuse the raw material directly into the desired shape at high temperatures. Material jetting combines slicing and melting to produce high resolution parts using a wide range of materials, from thermoplastics to ceramics.

Stereolithography (SLA) and digital light projector (DLP) 3D printing use photopolymerization, which exposes a liquid polymer resin to UV light to harden it as the laser or projector moves across the surface. This is a very precise process, but the resulting parts tend to be more brittle and will degrade with time.

Injection moulding and machining still play an important role in many industries, but 3D printing offers the flexibility to produce a much wider range of products in smaller batches. It’s ideal for rapid prototyping, allowing designers to iterate on their designs quickly and accurately without the cost of tools or the set up involved with traditional manufacturing. It’s also enabling businesses to replace expensive tooling or jigs with 3D printed alternatives, saving space and improving efficiency. For example, Pankl Racing Systems has replaced machined jigs and fixtures with 3D printed parts to cut costs and improve performance.